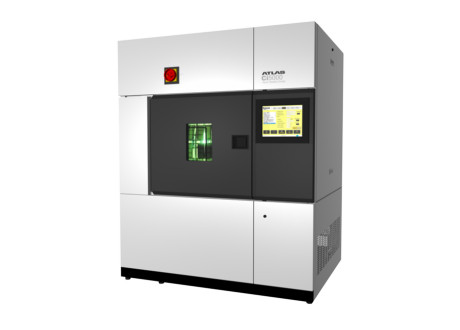

Environmental test chambers is used in the test of AEC-Q100 automotive electronic parts

The environmental test chambers is applied to the AEC-Q100 test standard for automotive electronic components testing. Automotive electronic components are divided into three categories, including IC, discrete semiconductors, and passive components. In order to ensure that these automotive electronic components meet automotive safety requirements The highest standard, the American Automotive Electronics Council (AEC, Automotive Electronics Council) is a set of standards designed for active parts [microcontrollers and integrated circuits.. etc.] [AEC-Q100], designed for passive components [[AEC-Q200], which regulates the product quality and reliability that must be achieved by passive components. AEC-Q100 is the automotive reliability test standard established by the AEC organization.

AEC-Q100 automotive IC product verification flow chart:

Condition finishing of environmental test chamber (temperature and humidity test):

Temperature and humidity with applied bias voltage, according to JESD22 A101: 85℃/85%R.H./1000h/bias.

HAST (HAST Highly Accelerated Stress Test, according to JESD22 A110): 130℃/85%R.H./96h/bias, 110℃/85%R.H./264h/bias.

Highly accelerated stress test without bias voltage, according to JEDS22-A118, equipment: HAST accelerated aging test chamber): 110℃/85%R.H./264h.

Unbiased damp heat, according to JEDS22-A101, equipment: constant temperature humidity test chamber): 85℃/85%R.H./1000h.

Temperature cycle, according to JEDS22-A104, equipment: Temperature Humidity Test Chamber:

Grade 0: -50℃←→150℃/2000cycles

Level 1: -50℃←→150℃/1000cycles

Level 2: -50℃←→150℃/500cycles

Level 3: -50℃←→125℃/500cycles

Grade 4: -10℃←→105℃/500cycles

PTC (power temperature cycle, according to JEDS22-A105, equipment: PCT Highly Accelerated Stress Test Chambers):

Grade 0: -40℃←→150℃/1000cycles

Level 1: -65℃←→125℃/1000cycles

Level 2~4: -65℃←→105℃/500cycles

HTSL (High temperature storage life, JEDS22-A103, equipment: Precision High Temperature Oven):

Plastic package parts: Grade 0: 150℃/2000h

Level 1: 150℃/1000h

Grade 2~4: 125℃/1000h or 150℃/5000h

Ceramic packaged parts: 200℃/72h

Environmental test chamber,AEC-Q100,Temperature Humidity Test Chamber,HAST Acceelerated Aging Test Chamber,PCT Highly Accelerated Stress Test Chambers,Precision High Temperature Oven-QINSUN INSTRUMENT LAB

评论

发表评论