Non-destructive testing (NDT) methods include a wide range of analytical techniques to evaluate a variety of materials, elements, welds, systems, etc., without causing any damage or harm to the sample. This article focuses on the different NDT methods used in the textile industry.

Textile testing instruments manufacturers use a variety of NDT methods for toxicological and other analytical tests to analyze their products for harmful substances such as allergens, heavy metals and even carcinogens. Several toxic metals such as cadmium, antimony, lead, chromium, mercury and zinc are either present in natural textile fibers, leached during the dyeing process or present in protective agents used to store textiles.

Vibrational spectroscopy has been a commonly used method for nondestructive testing of textiles because when light interacts with molecules on the textile surface, it produces vibrations specific to the functional groups or chemical bonds present in the material. These vibrations produce a unique spectral fingerprint that can be used to identify the material or element present in a textile product.

NDT Technology: A Brief Overview

The NDT technique has been in use for over thirty years and its main objective is to detect defects without affecting the operation of the equipment. The NDT method has several advantages over traditional testing methods, the most important being the reduction of sample waste. In addition, imaging-based testing methods enable the design of optimal production processes, resulting in improved product quality and quantity.

Some of the most commonly used NDT methods are eddy current, microwave ultrasound and acoustic emission. The specific method chosen for analysis is based on the type of object to be inspected or the type of defect to be identified.

Recent advances in optical NDT methods offer greater detection accuracy and sensitivity. A common type of optical NDT inspection includes infrared thermography. Recently, fiber optic sensors have also been used to measure the dynamic properties of materials.

NDT methods are powerful tools for detecting deterioration of silk, which is characterized by splits and tears that develop into powdery and fragile surfaces. Deteriorated silk is difficult to recover. It is difficult to analyze silk using traditional methods because treatment with metal salts accelerates deterioration and many times these samples become difficult to identify. NDT techniques overcome these difficulties and help curators and conservators to preserve the history of technical art and the condition of objects.

NDT methods in the textile industry

Spectroscopic techniques, such as Raman spectroscopy and polarization-attenuated total reflection infrared spectroscopy (pol-ATR), are commonly used to analyze the condition and composition of silk. In the textile industry, Raman or infrared spectroscopy is commonly used to characterize textiles and fabrics and to check the quality of raw materials. Two NDT techniques used to understand the condition and composition of silk are X-ray fluorescence (XRF) and near infrared (NIR) spectroscopy. As mentioned above, several NDT methods are used in the textile industry, some of which are described below.

Infrared Thermography

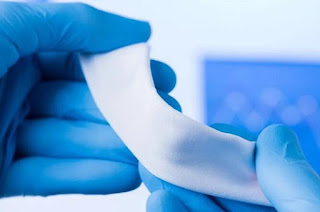

Infrared thermography (IRT) has recently been used as an NDT method to analyze the structure of adhesive-bonded textiles. Bonding textiles with adhesives has become a popular construction method in apparel manufacturing. Researchers report that

The spatial uniformity of the temperature distribution in the bonded area is related to the peel strength of the bond. IRT can be used to detect inhomogeneities in the heat distribution so that a good bond can be distinguished from a bad one.

IRT results can reveal the two-step adhesive distribution pattern that affects the peel strength of the bond during heat treatment of the sample, the scientists said. In addition, the Fast Fourier Transform (FFT) technique can also shed light on the temperature distribution patterns within the bonded seams of textile materials.

XRF and near-infrared spectroscopy

In the textile industry, XRF spectroscopy has been used to identify mineral dyes, weighting agents and mordants. Advances in analytical tools, ranging from large lab-based devices to hand-held portable XRF devices, are helping to evaluate historic textiles.

These instruments are battery powered and connected to a computer where the data is analyzed. Total reflection XRF (TXRF) was used to detect arsenic, chromium, lead, cadmium, cobalt, nickel, copper, mercury and zinc in various cloth samples. The scientists report that the elemental patterns of textile samples resemble "fingerprints" that can be determined by TXRF-spectroscopy.

Therefore, this technique is also used in forensic investigations to identify textile samples. Near-infrared spectroscopy has been used to identify various natural and synthetic fabrics. This technique is useful for analyzing strained regions of silk materials. Similar to XRF spectroscopy, near-infrared spectroscopy has also been used to study historical silk samples.

Pulse Echo (PE)

The pulse echo detection method introduces an acoustic beam into the textile sample, which passes through the raised baffle portion of the fabric and returns to the transducer. The sound returns to the transducer when it encounters a discontinuity within the sample. Dispersed signals or sound waves are processed to quickly identify textiles.

Terahertz (THz) technology

Electromagnetic waves in the frequency range between 0.1 terahertz and 10 terahertz are called terahertz waves. Terahertz wavelengths occur between microwaves and infrared. In terahertz non-destructive testing methods, terahertz radiation of known wavelength is introduced onto a textile sample and the reflected radiation is captured. The internal structure of the sample is determined by analyzing the changes in the terahertz signal. One of the advantages of this approach is that, unlike infrared thermal imaging, terahertz waves can penetrate opaque materials.

评论

发表评论