Textile testing equipment is a large category of professional testing equipment, mainly used to test the physical and mechanical properties of textiles. These properties include: reactivity (extension), abrasion resistance, penetration and more. The testing of these properties is of great significance for the application of textiles in industries and people's lives. Because the quality of textiles is ensured, it can ensure that clothing or other cultural items have good quality and service life.

Next, let us learn about the relevant knowledge of textile testing equipment

1. Common textile testing equipment

Common textile testing equipment includes tensile testing machines, abrasion testing machines, portable yarn counters, evaluation gloves, washing and dyeing benches, and more.

Tensile testing machine is a kind of equipment used to determine the tensile properties of textiles, mainly to measure the tensile limit, expansion ratio, stress-strain curve, elastic modulus, etc. of materials.

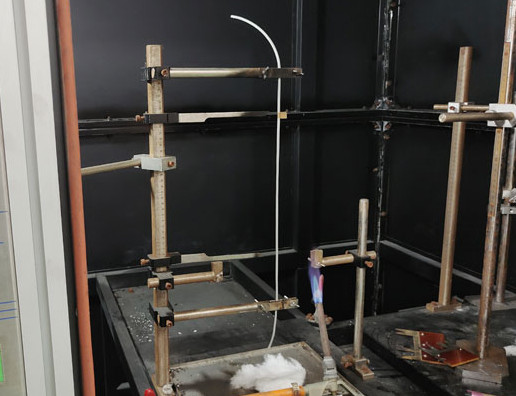

Abrasion testing machine is a kind of equipment specially used to test the wear position of textiles. It can quickly measure the wear performance of different materials under the same conditions.

Portable yarn counters can quickly measure the quality of yarns, fabrics, and woven products, which facilitates textile producers and users to better control production and use costs.

Evaluation glove is a kind of glove used to check and accept the production factory. By formulating the material and technical specifications of the glove, the quality and standard of the glove are evaluated to ensure the quality and quantity of the product.

The washing dyeing table can be used to test the dyeing degree of textiles and the color fastness of different dyeing agents, so as to ensure the normal use of dyeing agents and the quality of textiles.

2, the application of textile testing equipment

In the textile industry, textile testing equipment plays a very important role. Through these testing equipment, the production efficiency and quality of textiles can be greatly improved to meet people's continuous improvement requirements for textile quality.

First, it can help manufacturers control and monitor textile quality, such as thread strength and color fastness. This will help to ensure consistency and reliability of product quality, thereby making users feel trusted and satisfied.

Secondly, the growing demand brought about by the Internet and cross-border trade makes the product quality of textiles an important factor in consumer decision-making. Therefore, these test equipment can also be used to evaluate the competitor’s product quality and optimize in terms of product quality, thereby increasing market share and profit.

3. The development trend of textile testing equipment

With the continuous improvement of textile technology and the continuous increase of market requirements, textile testing equipment is also facing a new development trend.

First, test equipment will become increasingly intelligent. With the application of artificial intelligence and Internet technology, testing equipment can analyze data faster and provide customized solutions, thereby further improving production efficiency and quality.

Second, test equipment will become more and more integrated. With the development of the textile industry, we need to adapt to diverse demand patterns, and the adjustment and improvement of manufacturing details require comprehensive testing and evaluation through different textile testing equipment.

Although textile testing equipment will undergo some changes with technology and market changes, it still plays a vital role in the modern textile industry. It can improve production efficiency, control production quality, and at the same time help consumers trust textiles, so it can comprehensively improve the entire textile industry.

ps: (WLJCDM809)

评论

发表评论